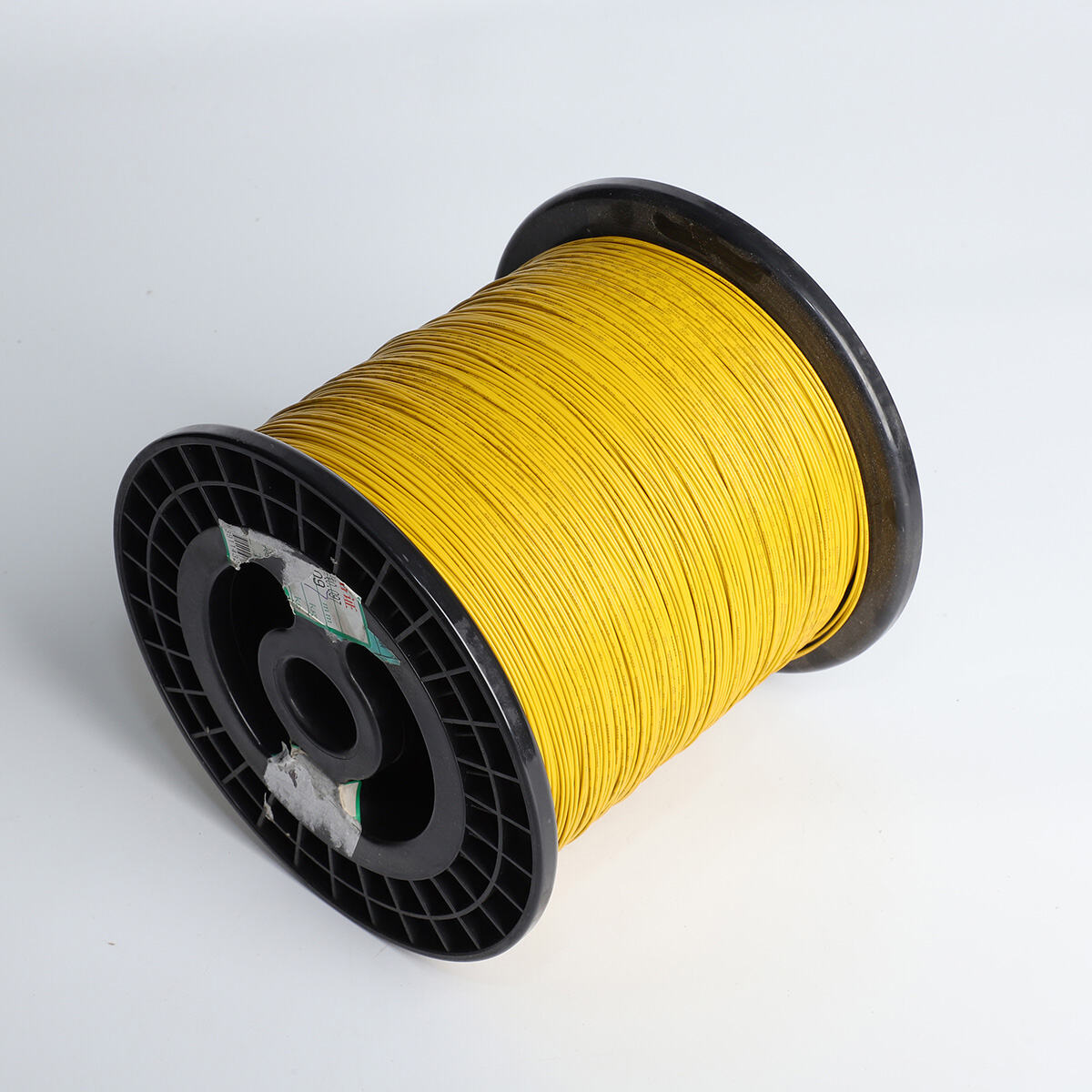

industrial electric wire and cable

Industrial electric wire and cable represents a fundamental component of modern manufacturing and infrastructure systems, serving as the backbone for electrical power transmission and signal distribution across diverse industrial environments. These specialized electrical conductors are engineered to withstand demanding operational conditions while maintaining consistent performance, reliability, and safety standards. Industrial electric wire and cable systems encompass a comprehensive range of products designed to meet specific voltage requirements, environmental challenges, and application demands within manufacturing facilities, processing plants, and heavy industrial installations. The main functions of industrial electric wire and cable include power distribution from electrical panels to machinery, motor control circuits for automated equipment, instrumentation and control signal transmission, and data communication networks essential for modern industrial operations. These conductors facilitate the seamless flow of electricity throughout complex industrial systems, enabling machinery to operate efficiently while supporting critical control and monitoring functions. Technological features of industrial electric wire and cable incorporate advanced insulation materials such as cross-linked polyethylene, thermoplastic elastomers, and specialized polymer compounds that provide superior electrical properties, chemical resistance, and thermal stability. The conductor cores utilize high-purity copper or aluminum alloys that optimize electrical conductivity while maintaining mechanical strength and flexibility. Industrial electric wire and cable applications span across petroleum refineries, chemical processing facilities, steel mills, automotive manufacturing plants, food processing operations, pharmaceutical production facilities, and power generation stations. These cables must perform reliably in environments characterized by extreme temperatures, corrosive chemicals, mechanical vibration, electromagnetic interference, and moisture exposure. The selection of appropriate industrial electric wire and cable depends on factors including voltage rating, current capacity, environmental conditions, installation method, and regulatory compliance requirements specific to each industrial application.