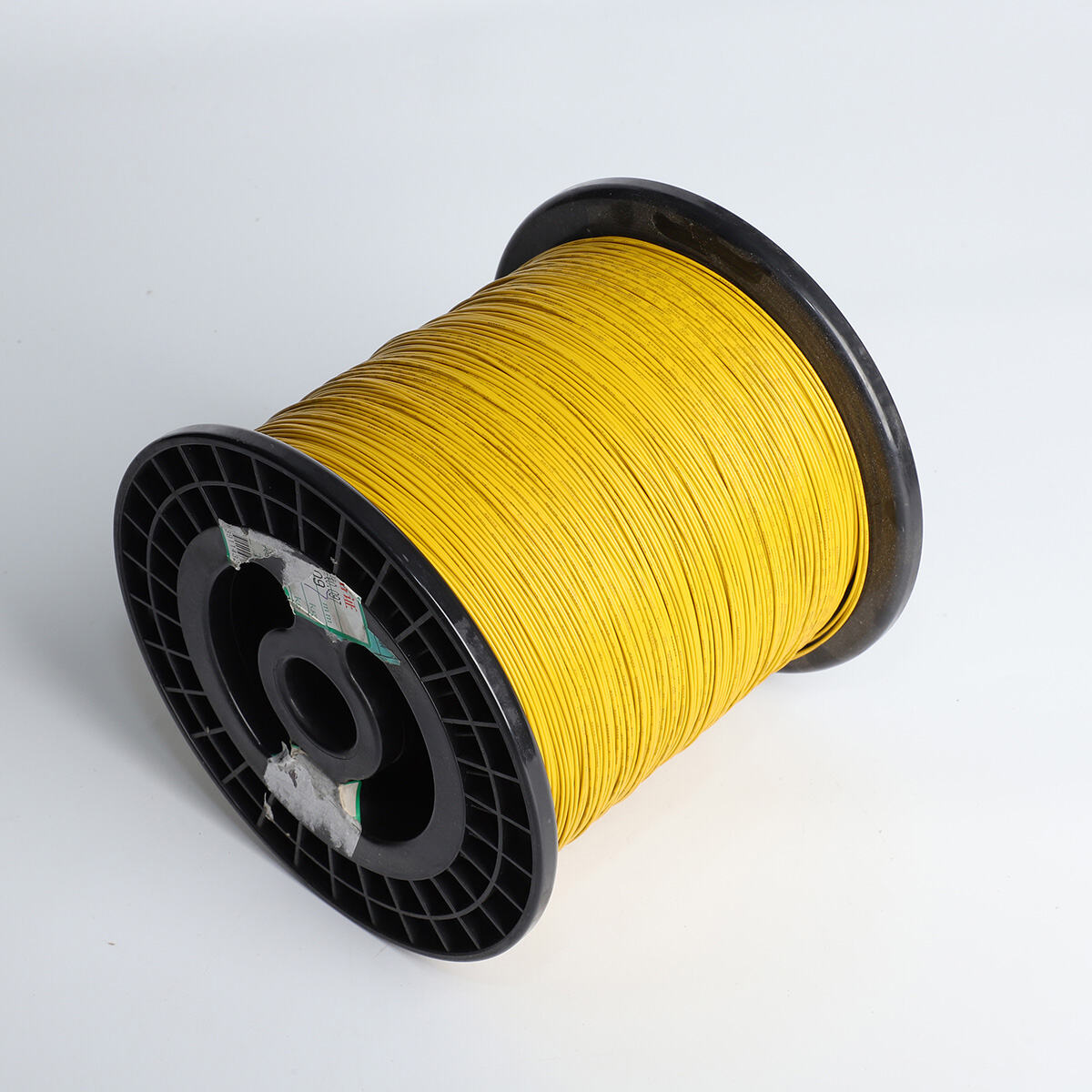

electric cable wire 10 mm

Electric cable wire 10 mm represents a crucial component in modern electrical infrastructure, serving as a robust conductor for medium to high-power applications across residential, commercial, and industrial settings. This specific gauge measurement refers to the cross-sectional area of the conductor, which directly impacts the cable's current-carrying capacity and voltage handling capabilities. The electric cable wire 10 mm typically features a solid or stranded copper conductor core, surrounded by high-quality insulation materials such as PVC, XLPE, or rubber compounds that provide excellent protection against environmental factors and electrical hazards. The technological features of electric cable wire 10 mm include superior conductivity properties that minimize power losses during transmission, ensuring efficient energy distribution throughout electrical systems. These cables undergo rigorous manufacturing processes that incorporate advanced extrusion techniques for insulation application and precise conductor sizing to meet international standards such as IEC, BS, or ASTM specifications. The insulation system employed in electric cable wire 10 mm offers exceptional dielectric strength, temperature resistance ranging from -40°C to +90°C depending on the material composition, and outstanding mechanical durability to withstand installation stresses. Applications for electric cable wire 10 mm span across various sectors including building wiring for main distribution panels, motor connections in industrial machinery, outdoor lighting circuits, and power supply lines for heavy-duty equipment. The cable's versatility makes it suitable for both fixed installations and flexible applications where movement is required. Installation methods for electric cable wire 10 mm include conduit systems, cable trays, direct burial with appropriate protection, and overhead mounting configurations. Safety considerations remain paramount when working with electric cable wire 10 mm, requiring proper circuit protection devices and adherence to local electrical codes to prevent overloading and ensure reliable operation throughout the system's lifespan.