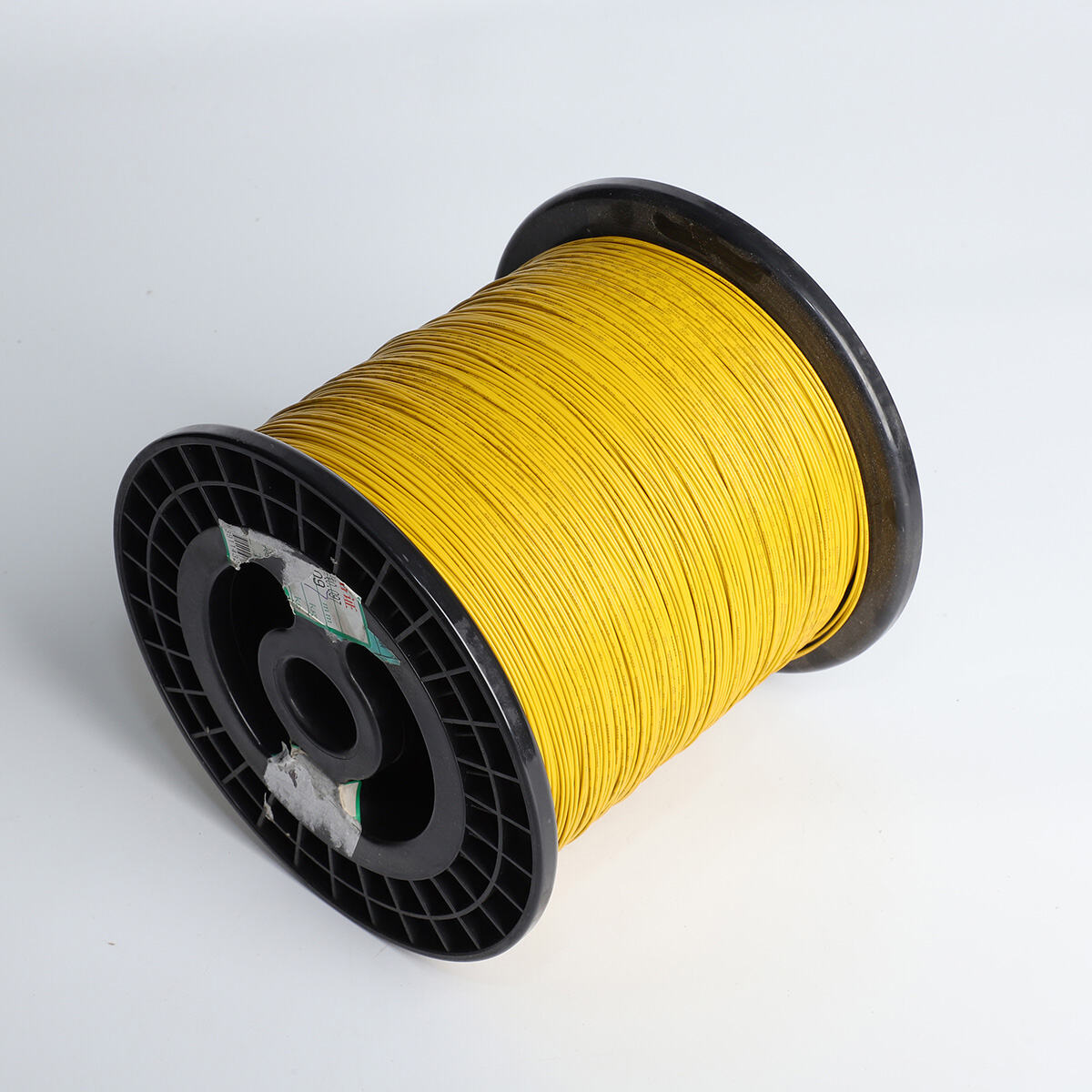

power cable wire diameter

Power cable wire diameter represents a fundamental specification that determines the electrical capacity, safety, and performance characteristics of electrical cables. This critical measurement defines the cross-sectional area of the conductor, directly influencing the cable's ability to carry electrical current safely and efficiently. Understanding power cable wire diameter is essential for engineers, electricians, and facility managers who need to select appropriate cables for various electrical installations. The diameter measurement encompasses both the actual conductor size and the overall cable dimensions, including insulation and protective sheathing. Power cable wire diameter specifications follow international standards such as AWG (American Wire Gauge) and metric measurements, ensuring consistency across different applications and regions. The selection of appropriate power cable wire diameter depends on multiple factors including current load requirements, voltage levels, installation environment, and distance considerations. Larger power cable wire diameter typically indicates higher current-carrying capacity, while smaller diameters are suitable for low-power applications. The relationship between power cable wire diameter and electrical resistance follows fundamental electrical principles, where larger conductors exhibit lower resistance and reduced voltage drop over long distances. Modern power cable wire diameter options range from extremely fine wires used in electronics to massive conductors employed in industrial power distribution systems. The manufacturing process for power cable wire diameter involves precise control of conductor materials, typically copper or aluminum, to achieve exact dimensional specifications. Quality control measures ensure that power cable wire diameter meets stringent industry standards for electrical performance and mechanical durability. Environmental considerations also influence power cable wire diameter selection, as temperature variations, moisture exposure, and chemical resistance requirements affect cable performance. The economic implications of power cable wire diameter choices impact both initial installation costs and long-term operational efficiency, making proper selection crucial for project success.