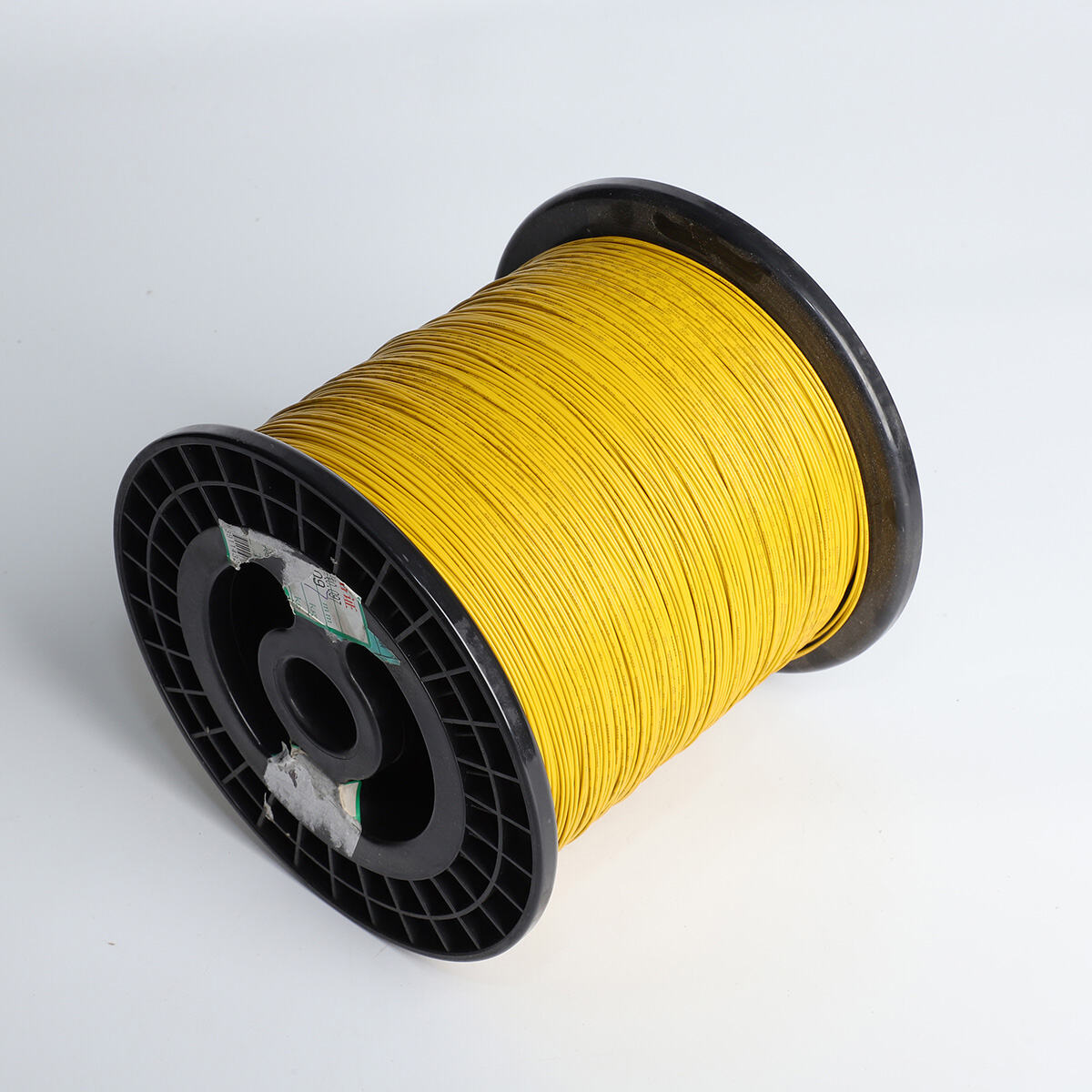

electric cable wire gauge

Electric cable wire gauge represents a standardized measurement system that determines the diameter and cross-sectional area of electrical conductors within cables. This critical specification directly impacts the current-carrying capacity, voltage drop characteristics, and overall safety performance of electrical installations. The electric cable wire gauge system employs numerical designations where smaller numbers indicate larger conductor diameters and higher current-handling capabilities. Understanding proper electric cable wire gauge selection ensures optimal electrical system performance while preventing hazardous conditions such as overheating, power loss, and potential fire risks. Modern electrical applications rely heavily on accurate wire gauge specifications to maintain efficiency and comply with safety regulations. The American Wire Gauge (AWG) standard serves as the primary reference system for electric cable wire gauge measurements in North America, while metric systems predominate in other regions. Electric cable wire gauge selection involves careful consideration of factors including maximum current load, circuit length, ambient temperature conditions, and installation environment. Professional electricians and engineers utilize comprehensive charts and calculations to determine appropriate electric cable wire gauge requirements for specific applications. The relationship between electric cable wire gauge and electrical resistance plays a fundamental role in system design, as thicker conductors provide lower resistance and reduced power losses. Temperature coefficients also influence electric cable wire gauge performance, requiring additional safety margins in high-temperature environments. Proper electric cable wire gauge selection directly correlates with installation longevity, energy efficiency, and operational safety. Industry standards mandate specific electric cable wire gauge requirements for different electrical loads, ensuring consistent performance across various applications. Advanced manufacturing techniques continue to improve electric cable wire gauge precision and reliability, supporting increasingly demanding electrical infrastructure requirements.